Accessible on cloud or deployed on private servers, Dolphin Service center seamlessly integrates with Dolphin ERP & Dolphin JobDor Mobile APP.

Dolphin Service Center is the ideal solution for repair centers and service center operations. Can be applied on a wide variety of Goods and Product types such as smartphones, televisions, home theater systems, Home Appliances, computers & laptops, medical equipment, wearable devices, smart appliances, marine equipment & even heavy equipment.

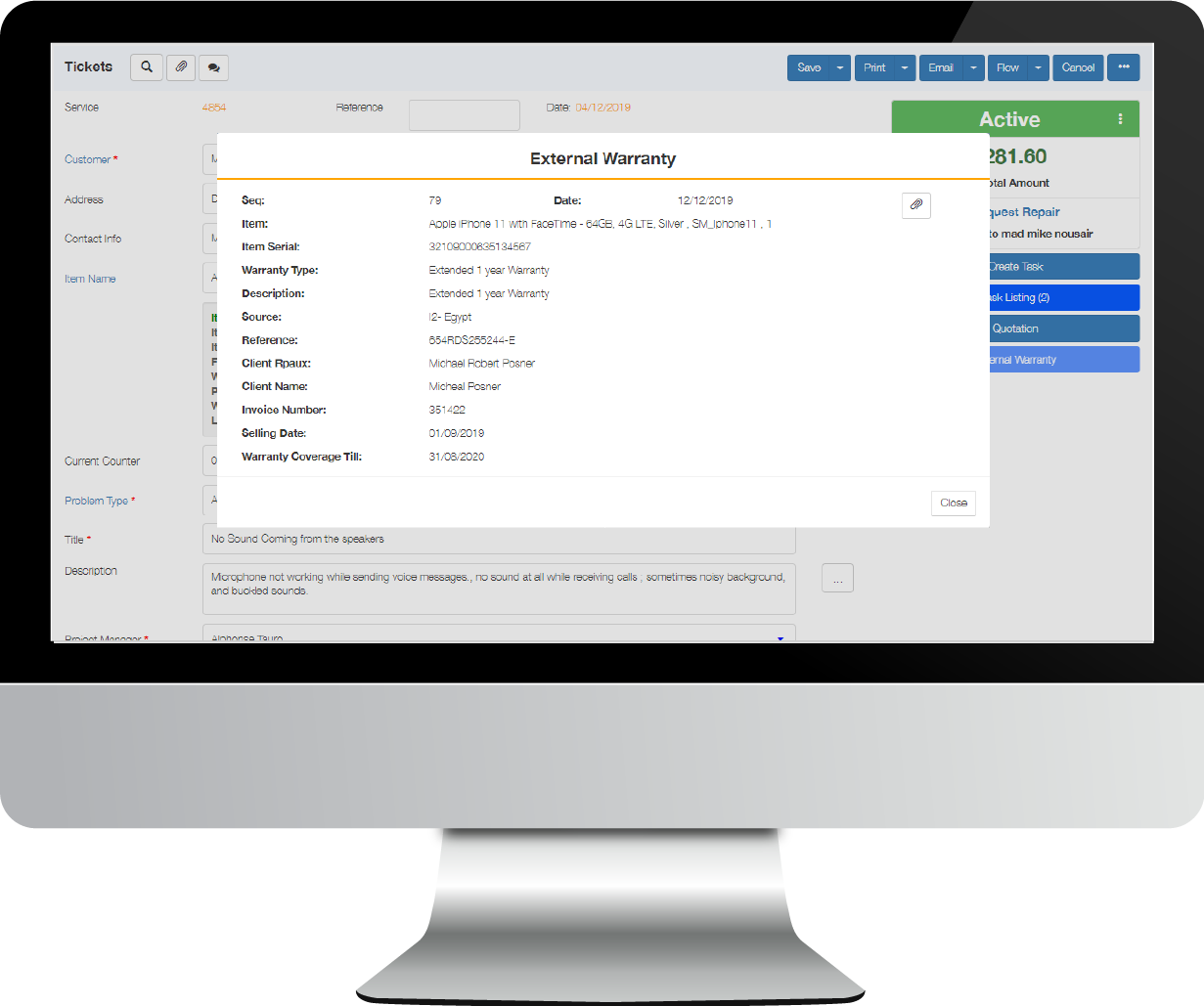

It has been designed for use in a Client Servicing Help Desk or a Call Center, for creating tickets (for example to register a complaint for technical defects). It can be applied in cases where repairs are covered by maintenance agreements (SLA,…) or even for ad-hoc repairs.

Dolphin Service Center makes it easy to manage repairs taking place at a workshop, in a repair center or even at the client’s premises, contributing to boost the company’s performance for efficient and on-time repairs, and to help ensure the best client satisfaction.